Ⅲ Main Equipments

1. De-capper

General Description

TBG300 de-capper ndiyo de-capping mudziyo wakagadzirwa zvinoenderana neinomhanya-mhanya 5 gallon barreled mvura mutsetse. Iyo de-capping kukwidziridzwa, kushushikana uye mbiya yekuvhara nzira inoshandisa yemahara-lubrication cylinder, isina kusvibiswa kwemafuta, yakachena uye yakarongeka.

Main Features

1) Shandisa yemahara-lubrication cylinder, isina kusvibiswa kwemafuta, yakachena uye yakarongeka.

2) Adopt inogadziriswa mbiya inovharira ruoko.

3) Stainless simbi chimiro, yakanaka uye nyore kuchenesa.

4) Outer Brusher

Sumo Pfupi

WST300 yekunze brusher ndiyo yekuchenesa midziyo yakagadziridzwa zvinoenderana nekumhanya kwepamusoro uye kudiwa kwe5 gallon barreled mvura mutsetse.

Main Features

1) Rotary yekuchenesa uye nzira yekufambisa ine yakapusa chimiro chiri nyore kugadzirisa.

2) Adopt giya kutapurirana, nekukurumidza uye kugadzikana.

3) Stainless simbi chimiro, yakanaka uye nyore kuchenesa.

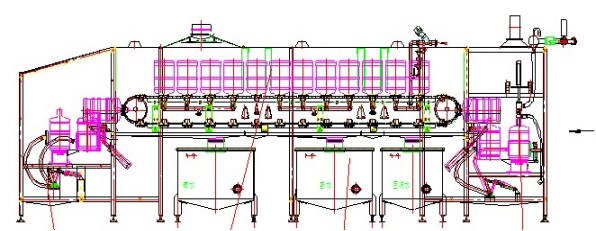

2.QGF-300 Rinser/Filler/Capper

General Description

QGF300 rinser/filler/capper monobloc midziyo yepamberi yakagadziridzwa pahwaro hwetekinoroji yepasi rose uye zvinoenderana nemaitiro ekumhanya kukuru uye otomatiki kuvandudza kwechinwiwa muChina.

Main Compositions

Rinsing/kuzadza/capping monobloc inoumbwa neotomatiki bhodhoro loader, rinser, pombi system, nzira yekufambisa, filler, uye yekuona mudziyo.

Automatic Bhodhoro Loader

General Description

1) Chigadziko chemuchina chinoumbwa nesimbi isina tsvina ndiro uye Stainless simbi square pombi. Iine zvakanakira kusimba kwepamusoro, kusimba kwakanaka, huremu huremu, kutaridzika kwakanaka, kutarisa kwakanaka uye kuchenesa kuri nyore.

2) Iyo bhodhoro yekurodha michina inotora 90 ° silinda yekupidigura michina, yakagadzikana uye yakavimbika.

3) Kudyisa bhodhoro uye kusunda nzira inoumbwa nebhodhoro rekusundira rack uye bhodhoro kusunda silinda. Basa rayo nderekusundidzira mabhodhoro pabhodhoro-n conveyor kune bhodhoro rekutakura hopper.

Kushanda Nheyo

Mabhodhoro asina chinhu anotumirwa kumabhodhoro ekurodha conveyor kubva mubhodhoro-mu conveyor. Mushure mekunge mabhodhoro abata switch yekufamba pabhodhoro rekutakura conveyor, PLC ita kuverenga kushanda. Paunenge uchiverenga mabhodhoro mana agadzirira, bhodhoro rekudyisa nekusundidzira silinda rinoita kusunda bhodhoro rekusundidzira tsvimbo kusunda mabhodhoro asina chinhu pane bhodhoro rekurodha conveyor kune bhodhoro rekutakura hopper. Bhodhoro rakati twasu muhopper uye bhodhoro rekurodha yekuona sensor rinoona kuti bhodhoro riri muhopi rave kugadzirira uye rinotumira chiratidzo nekukasira kugadzira bhodhoro rekupidigura silinda chiito kusundira bhodhoro rekurodha hopper inotendeuka 90 ° uye inoshandura bhodhoro kuti rive chinzvimbo. . Panguva ino, muromo webhodhoro wakatarisana negwara rakanaka rekugadzirisa bhodhoro kapu yeinotakura yerinser. Bhodhoro rekusundidzira & kurodha sensor rinoona kuti bhodhoro rave rakagadzirira uye bhodhoro kusunda & kubata silinda zviitiko kusundira bhodhoro mukapu yekumisikidza yerinser's conveyor uye inoona level yekurodha mabhodhoro. Rinser's conveyor inofambiswa nerinser yekutyaira michina uye mabhodhoro asina chinhu anoenda kumberi kumuviri wemuchina.

Rinser

General Description

1) Chigadziko chekusuka chakasungirirwa nendiro yakabhenda yesimbi isina tsvina uye pombi yesimbi isina tsvina. Iine zvakanakira kutaridzika kwakanaka, kusimba kwepamusoro, kuomarara kwakanaka, huremu huremu uye kuchenesa kuri nyore.

2) Riser conveyor inoumbwa neanoshanda uye passive sprocket, cheni, bhodhoro rinobata ndiro uye bhodhoro rekugadzirisa kapu. Iyo ketani uye sprocket zvakagadzirirwa zvakanaka kuti zvive zvakanyanya zvesainzi uye zvakakwana.

3) Rinser yekutyaira michina inosundirwa necylinder kuita kuti bhodhoro riri munzvimbo yega yega yekushanda rigare kwenguva yakati. Iyo ketani inoverengerwa zvakanyatsoenderana otomatiki bhodhoro kurodha uye kudonhedza zvinzvimbo kuti ive nechokwadi chaicho chinzvimbo chese otomatiki kumhanya.

Filler/Capper

General Description

1) Filler base yakasungwa neyakabhenda simbi isina simbi ndiro uye Stainless simbi square pombi. Iine zvakanakira kutaridzika kwakanaka, kusimba kwepamusoro, kuomarara kwakanaka, huremu huremu uye kuchenesa kuri nyore.

2) Ivhavha yekuzadza inotora musoro mutsva wekuzadza. Ichiri kuzadza, silinda inogadzira pasi kufamba, uye kuzadza mavharuvhu emitambo muviri unobata muromo webhodhoro kudzvanya chitubu uye kuvhura vharafu yekuzadza.

3) Cap mudziyo unoshandiswa kuchengetedza uye kutumira caps. Kana cap sorter ichida macaps ekuwedzera, chikwiridzo chinotakura zvivharo kune chigaba checap chinotsvedza zvivharo zvakatsiga uye nekukasira kupinda mu cap sorter.

4) Cap sorter inonyanya kuumbwa nemota inotenderera tray, cap chute uye shell. Basa rayo ndere kuunza zvivharo mubhokisi mu cap chute nemotor round tray inotenderera uye kugadzira ma caps mu chute kudzika uye chinzvimbo mukurongeka nechakakosha michina.

5) Capper base yakashongedzwa nesimbi isina simbi ndiro uye Stainless simbi square pombi. Iine zvakanakira kutaridzika kwakanaka, kusimba kwepamusoro, kuomarara kwakanaka, huremu huremu uye kuchenesa kuri nyore.

6) Capping mashandiro ndeyekuita capping yebhodhoro rakazadzwa necap kuti uwane yekuisa chisimbiso. Inotora pre-cap type capping.

7) Bhodhoro pasi meshini inoumbwa nebhodhoro rinobata hopper, bhodhoro pasi rack uye bhodhoro pasi silinda. Inotora 90 ° cylinder inoputika chimiro, yakagadzikana uye yakavimbika.

8) Bottle-out pushing mechanism inoumbwa nebhodhoro rekusundidzira ndiro, bhodhoro rekusundira rack uye bhodhoro kusunda silinda. Inonyanya kuitirwa kusunda bhodhoro rakachena pane conveyor.

3. Barel Conveyor

General Description

The kumhanya simba kunyatsoshanda ane chokuita conveyor collocation .Izvo zvinofanira kufunga kwekanguva kumisa izvo hazvifaniri kukanganisa yapfuura chikamu achimhanya uyewo coordination pamwe kuruboshwe chikamu. Yedu yekugadzira mutsara dhizaini inotarisisa mutengi investimendi uye kushandisa kunyatsoita.

Inounza muGermany maitiro uye yakagadzira dhizaini. Zvizhinji zvezvikamu zvinotora punching uye kukotama, iyo ine yakanaka kuomarara, kureruka uye nyore kuchinjana. Kufambisa kwakagadzikana, kugadzirisa kuri nyore, kunoshanda kune dhayamitaφ40~φ110 mm bhodhoro. Iyo ine yakazara bhodhoro sensor muchikamu chega chega, Yese chikamu chinongedzo chekubatanidza. , iyo inosangana nezvinodiwa zvekutsvaga.

Main Features

1) Muenzaniso: SC00

2) Material: simbi isina tsvina

3) Empty barrel conveyor mota: 0.55KW/unit

4) Yakazara dhiramu conveyor mota: 1.1KW/unit

4. Chiedza Kuongorora

Sumo Pfupi

Chiedza chekuongorora bhokisi rakafukidzwa nesimbi isina tsvina, ine yakakodzera uye yakasununguka chiedza chenyika yehutsanana mwero, iyo inogona kuongorora zvakajeka kusachena, kutadza uye zviyo.

Technical Data

● Simba remwenje pombi: 20W

● Nhamba yepombi yemwenje: 3

5.Automatic gallon film package machine

1. Packaging performance yakakwira, mashandiro emuchina anoderedza mutengo wevashandi; kurongedza kumhanya kunogona kusvika 600 mbiya/awa kusvika 2500 mbiya/awa, kuchengetedza vashandi vaviri kana vana, kuchengetedza mutengo webasa we100,000 yuan pagore, asiwo zvakanyanya kuderedza mutengo wemabhegi. Mutengo wemembrane wekare shanu gallon bucket lifter ndeye 0.1 kona, uye mutengo wemembrane yemuchina weatomatiki webhegi ndeye 6-8 mapoinzi.

2. Mushure mekuvhara shrinkage chisimbiso, bhegi rebhakiti rinopindirana nekunze kwekunze kwebhakiti, iyo yakanaka uye yakabatana.

3. Firimu yepurasitiki inogona kuchengetedza bhakiti uye kuderedza kupfeka.

Iwo makuru maficha emvura yakavharwa otomatiki bagging muchina ndeaya anotevera:

1. Conveying system: Frequency shanduko inogona kukurumidza kushanda.

2. Chimiro chikuru: 304 simbi isina tsvina.

3. Kupisa-kutema kutonhora mode: yepakati kudzvinyirira mhepo-yakaoma kutonhora.

4. Sleeve mode: Kutsika mota yakabatsira firimu yekupinda modhi.

5. Kuisa chisimbiso: electric wire pressure inopisa-kucheka bag sealing mode.

6. Barel feeding mode: kuona otomatiki yekudyisa mbiya, otomatiki kutapurirana.

7. Equipment tsanangudzo: 3500 mm * 850mm * 1600 mm, 600 mm conveyor bhandi kubva pasi.

8. Zvishandiso zvechigadzirwa zvinoshandiswa: 5 gallon barrel kana tsika yetsika. Uniform tsanangudzo dzinodiwa.

9. Membrane tsanangudzo: 680-720 mm kureba, 0.006-0.015 mm muukobvu, 350 mm mudhayamita, hapana magetsi akamira, maronda akasimba.

10. Maximum mutoro wekufambisa basa: 20KG / 0.5m / s.

11. Kudzivirirwa kwekuchengetedza: kuchengetedzwa kwemagetsi.

Nguva yekutumira: Nov-30-2022